Innovative CERODEM® AlCrN PVD coating revolutionizes valve technology

Innovative CERODEM® AlCrN PVD coating revolutionizes valve technology

When valves reach their limits - and how a new coating changes that

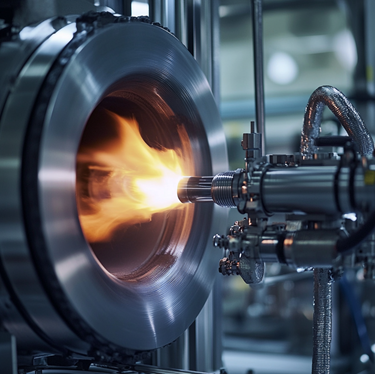

Extreme heat. Aggressive chemicals. Constant mechanical stress.

In the world of industrial valves, these stresses are part of everyday life - and they take their toll: wear, corrosion and failures that cost time and money.

But what if there was a solution that not only protected valves, but also made them virtually indestructible?

The answer: the new CERODEM® AlCrN PVD coating

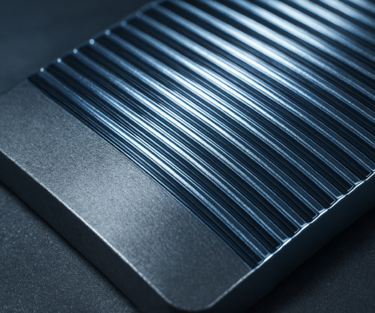

Our newly developed sputtered CERODEM® AlCrN PVD coating (aluminum-chromium-nitride) sets new standards in surface technology. It was specially created for applications where conventional coatings have long since reached their limits.

What makes AlCrN so special?

- it withstands temperatures of up to 700 °C - without any significant corrosion damage.

- it gives valves an extremely hard and wear-resistant surface.

- it is applied at just 180 °C - perfect for heat-sensitive materials.

and it provides smooth, rework-free surfaces that minimize friction and improve tightness.

Real success: The case story

A leading manufacturer of energy systems was facing a problem: its valves in high-temperature environments were regularly failing. The consequences were costly downtimes and high maintenance costs.Nach dem Umstieg auf unsere CERODEM® AlCrN-PVD-Beschichtung änderte sich alles:

- doubled maintenance intervals

- significantly reduced spare parts costs

- improved efficiency due to low-friction valve movements

The result: greater operational reliability, less downtime and a sustainable reduction in overall costs.

For whom is this technology a game changer?

Our AlCrN PVD coating is ideal for companies that want to take their valve technology to a new level - especially in:

✔️ Energy and power plant industry

✔️ Chemical production plants

✔️ Automotive technology (e.g. injection systems, exhaust gas recirculation)

Where heat, pressure and aggressive media prevail, AlCrN shows its full strength.

Conclusion: An investment in future security

Our sputtered CERODEM® AlCrN PVD coating makes the difference: it protects valves better, drastically extends their service life and sustainably reduces operating costs.

Make your processes more resilient, efficient and future-proof.