Surface solutions for friction control

Friction control for greater efficiency of machines and tools

Surface effects such as friction and wear have a significant influence on the functionality of machines and tools. Modern surface technology improves energy efficiency, drive performance, maintenance intervals and resilience. Advanced coatings replace liquid lubricants, minimise friction and offer wear protection. Technologies such as galvanic and chemical coatings, PVD/PACVD and thin films are central to machine components, plain bearings and tools. Sometimes an increase in friction coefficient is required for precise screw connections, for which dispersion coatings with particles are used. Our development department creates customised surface solutions for individual requirements, as there are also a wide variety of approaches to friction control.

Our different coating solutions

Galvanising

Electroplating technology is essential for reducing friction in coating technology. It comprises electrochemical processes for depositing electrically conductive metal layers on metal substrates. The relevant coatings include hard chrome, pearl chrome, bright chrome, nickel and anodising. These coatings effectively reduce friction, which is crucial in areas such as bearings and precision mechanics. This technique improves sliding properties and reduces wear caused by friction, which increases the service life and efficiency of components.

PVD/PACVD

PVD/PACVD is an advanced coating process that is particularly effective in controlling friction. Plasma deposition in a vacuum chamber produces thin, uniform ceramic hard coatings that improve hardness and wear resistance and thus reduce friction. The removal of oxides or water from surfaces optimises adhesion, which makes PVD/PACVD useful for various industrial sectors. PVD/PACVD is a key technology for low-friction industrial solutions.

Chemical layers

Chemical nickel coatings are of great importance in friction control. These coatings have uniform layer thicknesses, high hardness and pronounced wear resistance. These properties are crucial for reducing friction in applications involving components with complex shapes, holes, cavities and undercuts. Electroless nickel plating creates layers that not only provide wear protection, but also minimise friction between moving parts.

Hybrid

Hybrid coatings that combine galvanic, chemical and PVD/PACVD processes offer effective friction control. These coatings adapt to customer-specific requirements and enable precise coating thickness control and improved adhesion through galvanic processes. Chemical processes contribute to friction reduction with corrosion protection. PVD/PACVD technologies improve resistance to abrasive influences. This synergy of different technologies results in coating systems that minimise friction between materials while providing corrosion protection.

An overview of our product solutions in the field of medical technology.

Efficient coatings to reduce friction and wear in industrial applications

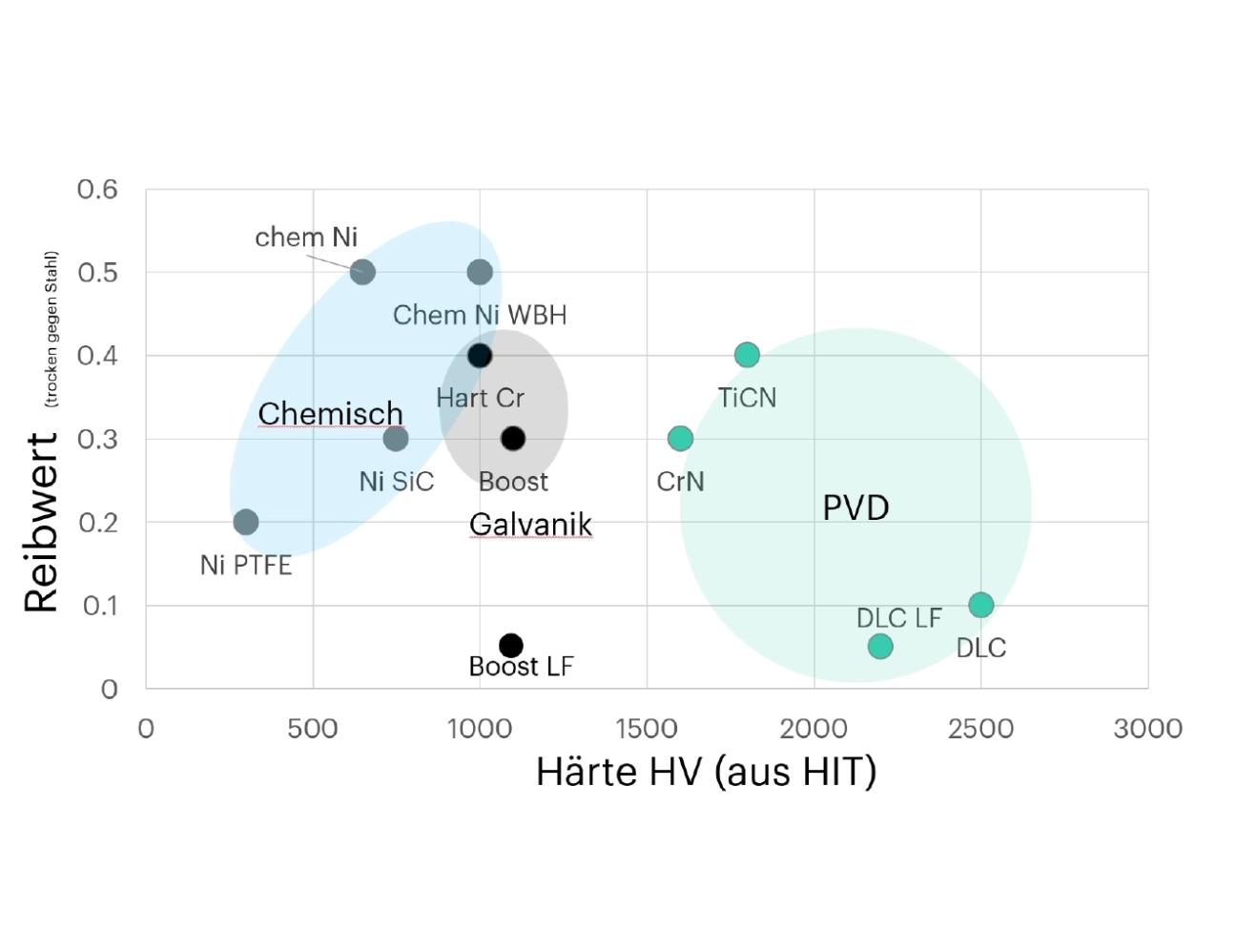

Figure: Coating systems friction reduction

Challenges in the area of friction

High friction in machine components leads to energy loss, increased wear and rising operating costs. This is a critical factor for efficiency and profitability, especially in demanding industrial sectors such as the automotive and aerospace industries.

Coating components with special layers to reduce friction offers an advanced solution. These coatings must be carefully selected and applied to maintain the functionality and efficiency of the machines.

The transformative effect of friction-reducing coatings

By reducing the coefficient of friction, these coatings improve energy efficiency, extend the service life of components and increase the reliability of machines and systems. They enable higher performance and reduce operating costs at the same time.

Technically speaking, friction-reducing coatings enable machines to be optimised and promote innovation. Economically, they lead to savings in energy consumption and maintenance costs, strengthen the market positioning of products and contribute to sustainability.

Friction-reducing coatings are an effective solution for tribological challenges. They improve the performance and efficiency of machines and contribute to more sustainable production.

Figure: Electroless nickel-DLC hybrid coating on a copper component