Your partner in the field of

energy and electronics.

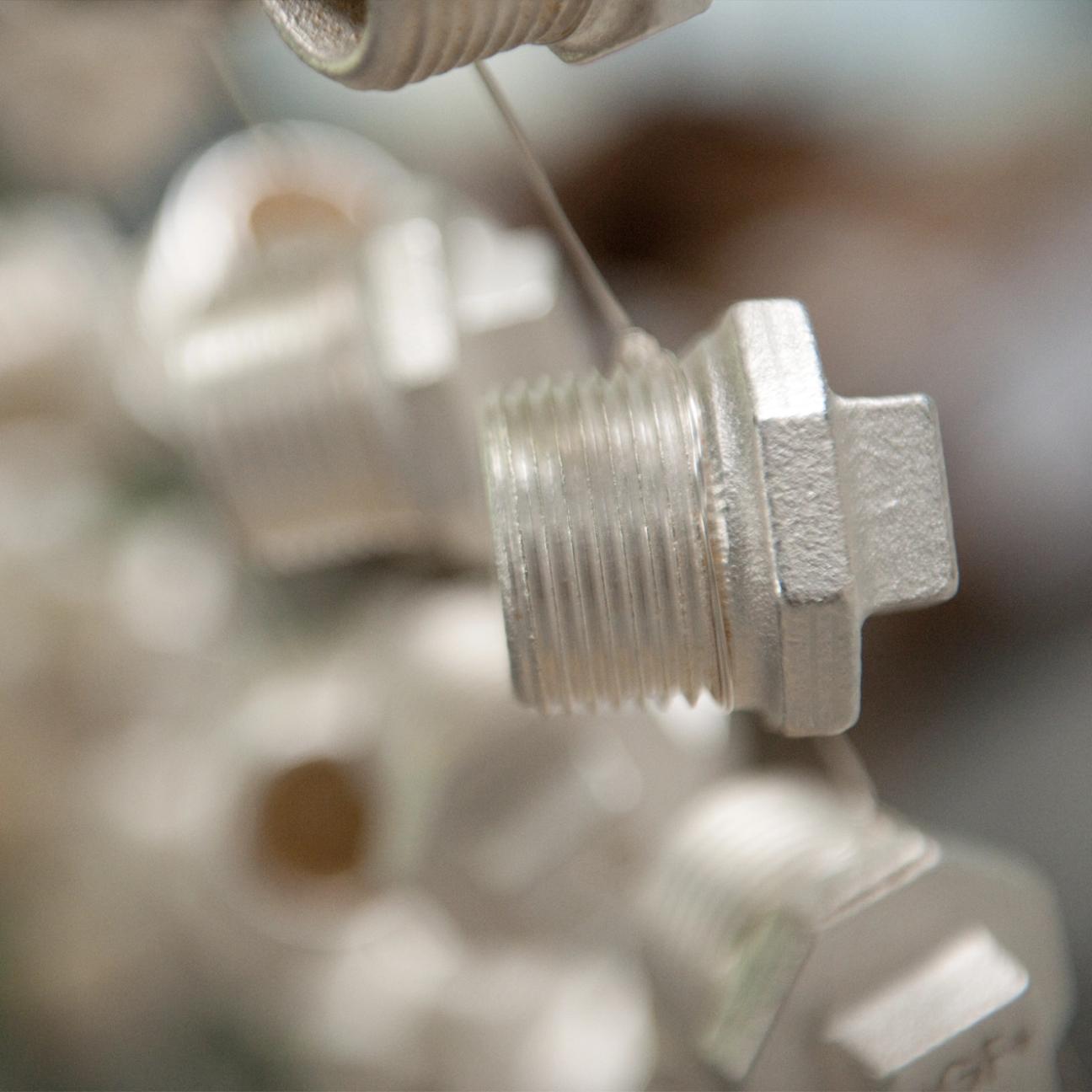

Surface coating for improved conductivity, stable electrical contacts and for many other requirements

In the energy and electronics industry, surface coating plays a crucial role in optimising electrical properties. Innovative surface coatings not only achieve improved conductivity and more stable electrical contacts, but also ensure better dielectric strength. The surface technology requirements for electrical systems in the energy and electronics sector are diverse. A precisely customised functional coating can help to increase the efficiency of energy transmission systems and improve the reliability of electronic components. Our wide range of surface processes, including chemical, galvanic, PVD/PACVD and hybrid processes, enables customised solutions for the challenges in the energy and electronics industry.

Insight into our customised solution for a customer in the energy & electronics sector

Innovative coating solutions for busbars

Busbars are indispensable components in the energy and electronics industry that ensure efficient power transmission. However, both copper and aluminium, from which they are made, can quickly form oxide layers that increase the contact resistance at the connection points and can even lead to total failures in aggressive environments.</p

To overcome this challenge, we have developed an innovative solution: coating the busbars with tin or nickel-tin. These electroplated tin layers offer excellent electrical properties and high oxidation resistance. We often combine these layers with an electroplated or chemically deposited nickel plating underneath, which acts as a diffusion barrier. These processes are RoHs-compliant and can be used for both rack and barrel coating.</p

The versatility of tin and nickel-tin coatings for busbars

The technical superiority of a tin or nickel-tin coating lies in its effective protection of the conductor rails against corrosion, even in aggressive environments. The high oxidation resistance of the tin layers also ensures low contact resistance, which enables efficient current transmission. The good solderability of tin surfaces is used in numerous applications to ensure a reliable connection between busbars and electronic components. Electroplated or chemically deposited nickel plating enhances corrosion protection and prevents unwanted whisker formation on the tin layers. Tin and nickel-tin coatings contribute to the longevity of the system by reducing costly maintenance and repair work. The excellent electrical properties minimise energy losses and improve the efficiency of electrical systems. In addition, the coating solution contributes to the overall safety of the system by reducing the risk of electrical short circuits.