Surface solutions for wear protection

Avoidance of material loss through functional surface technology

Material loss inevitably leads to a shortened service life. By optimising wear protection, objects can be protected against this wear with the help of suitable surface treatment. Surface abrasion can be caused by grinding, rolling, impact, scratching, chemical and thermal loads. Our surface solutions against abrasion, adhesion, surface fatigue, surface disintegration and tribo-oxidation are therefore extremely diverse and are continuously optimised to meet the individual needs of our customers. We offer a wide range of surface solutions against wear, which are adapted and optimised according to customer requirements.

Our different coating solutions

Galvanising

Electroplating is a central component of coating technology against corrosion. It involves electrochemical processes for the deposition of conductive layers, usually metals, on metal substrates. The most important coatings include hard chrome, bright chrome, nickel and anodising. These offer protection against corrosion and wear and improve the appearance of products. The choice of substrate depends on its electrical conductivity. These coatings make metal components in various industries more durable and resistant to environmental influences.

PVD/PACVD

In the context of wear protection, PVD (physical vapour deposition) is an important coating process. In this process, ceramic hard material layers are deposited in a vacuum chamber using plasmas. These layers are thin and uniform, which leads to improved hardness and wear resistance properties. A key advantage of PVD/PACVD is the removal of oxides and water from surfaces, which improves adhesion. This makes PVD/PACVD particularly valuable for various industrial applications, from tool coatings to decorative surfaces. PVD/PACVD is considered a key technology for customised, wear-resistant solutions in modern industry.

Chemical layers

Chemical nickel coatings, produced without external power supply, offer excellent wear protection thanks to uniform coating thicknesses and high hardness. These coatings are particularly suitable for components with complex geometries such as holes and cavities. Their application is versatile, suitable for steels, copper and aluminium alloys as well as ceramics and glass. This method is popular in industries with high load requirements where durability is crucial.

Hybrid

Hybrid coatings, a combination of galvanic, chemical and PVD/PACVD processes, offer customised solutions in the field of wear protection. These technologies create a multiphase coating package that is individually tailored to functional requirements. The galvanic processes in these coating systems ensure precise control of the coating thickness and improve adhesion. Chemical processes contribute to corrosion protection, while PVD/PACVD technologies increase resistance to abrasive influences. Together, these techniques provide comprehensive protection against wear by optimising the mechanical and chemical properties of the surface.

An overview of our product solutions in the field of medical technology.

Efficient solutions against abrasive wear

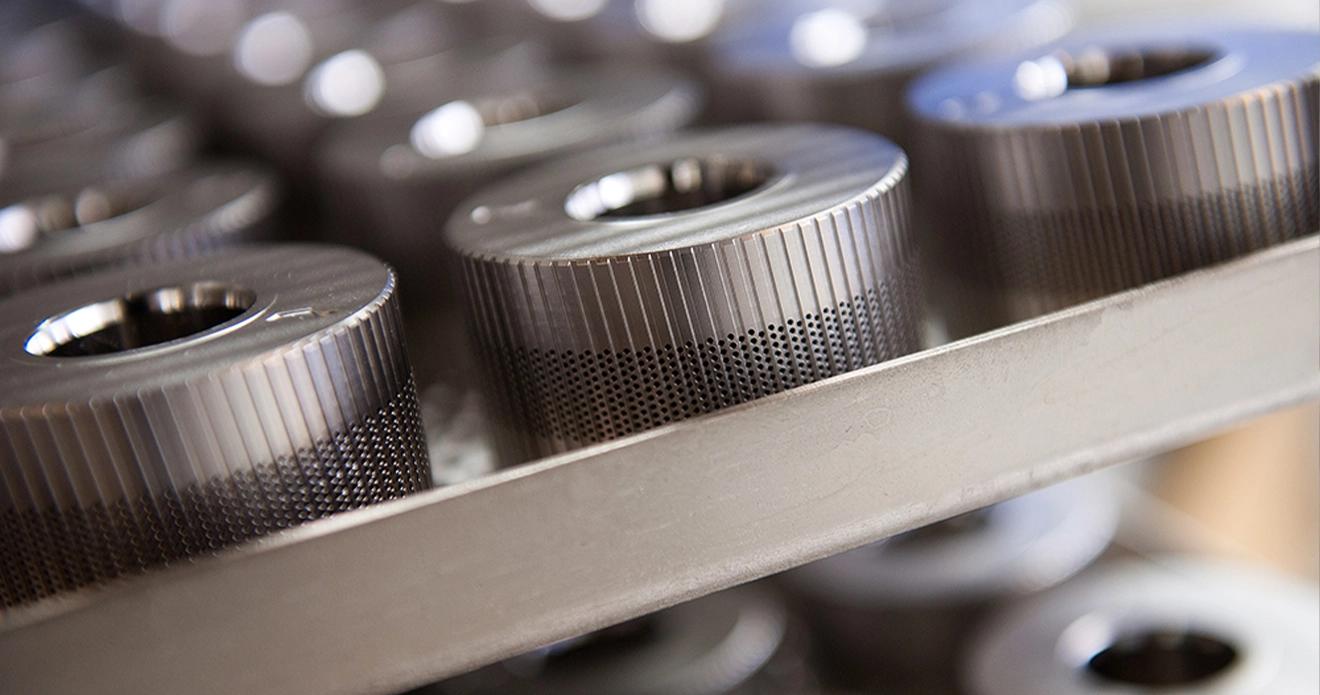

Figure: Abrasion due to particles

The challenge of steel components

In many industries, such as mechanical engineering, mining and transport, steel components are indispensable. However, continuous exposure to abrasive materials leads to premature wear, impairs functionality and increases the risk of failure.

The development of protective coatings against abrasive wear requires materials and techniques that offer high hardness and adhesion without compromising the mechanical properties of the steel. The uniform coating must maintain functionality even with complex geometries and be resistant under variable operating conditions.

Advantages and technical and economic benefits

Protective coatings extend the service life of components, reduce maintenance costs and increase machine efficiency by reducing wear. They prevent direct contact between steel and abrasive materials, thereby improving the performance of the applications.

Technically, protective coatings enable the use of steel components in extreme environments. Advanced materials such as ceramics and hard metals increase hardness and wear resistance. Economically, the longer service life leads to lower total cost of ownership due to reduced downtime and repairs. This increases productivity and profitability and gives companies a competitive advantage.</p

Protective coatings offer an effective solution for improving steel components, reducing material losses and enabling more reliable and cost-efficient use in a wide range of industrial applications.

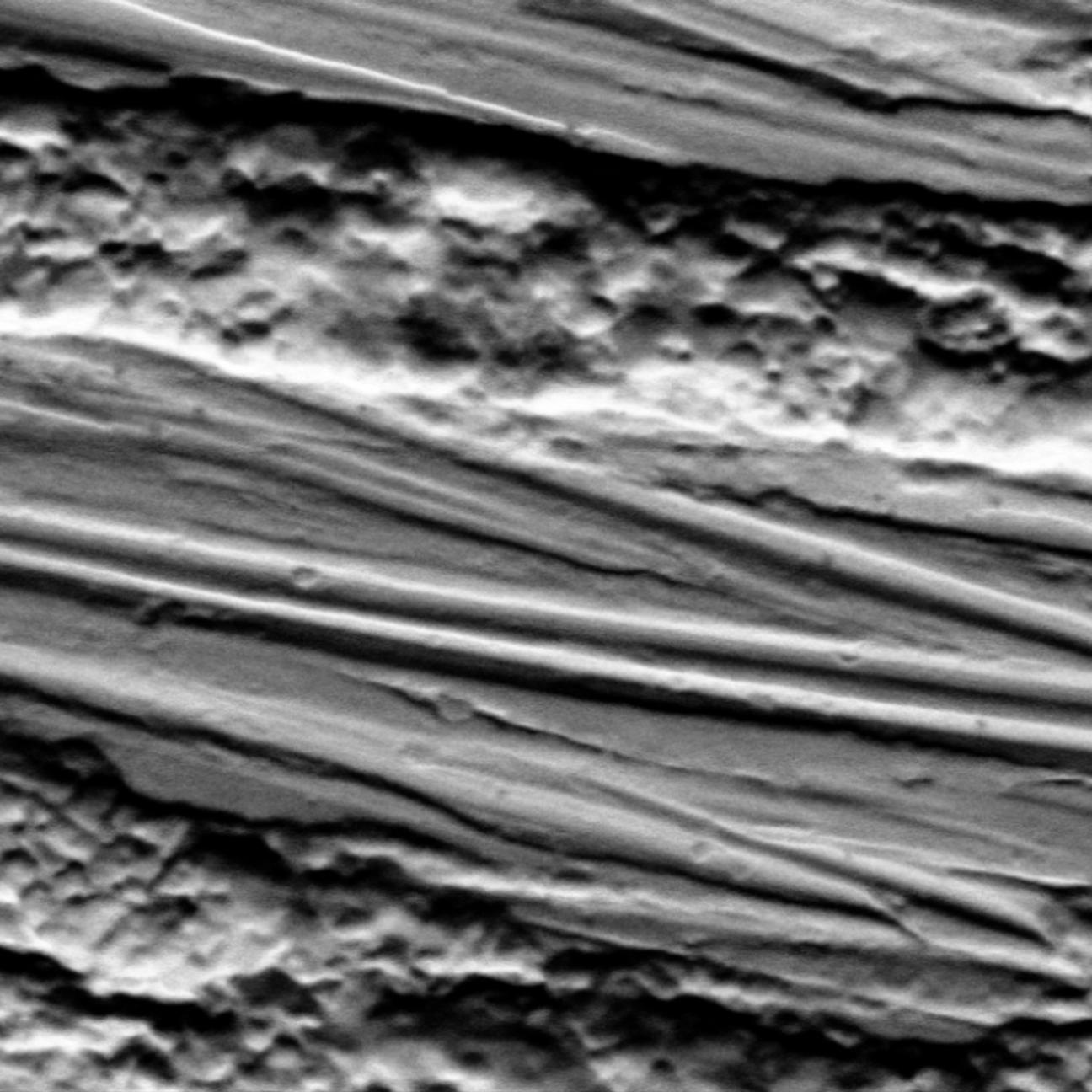

Image: Abrasion marks on a worn surface