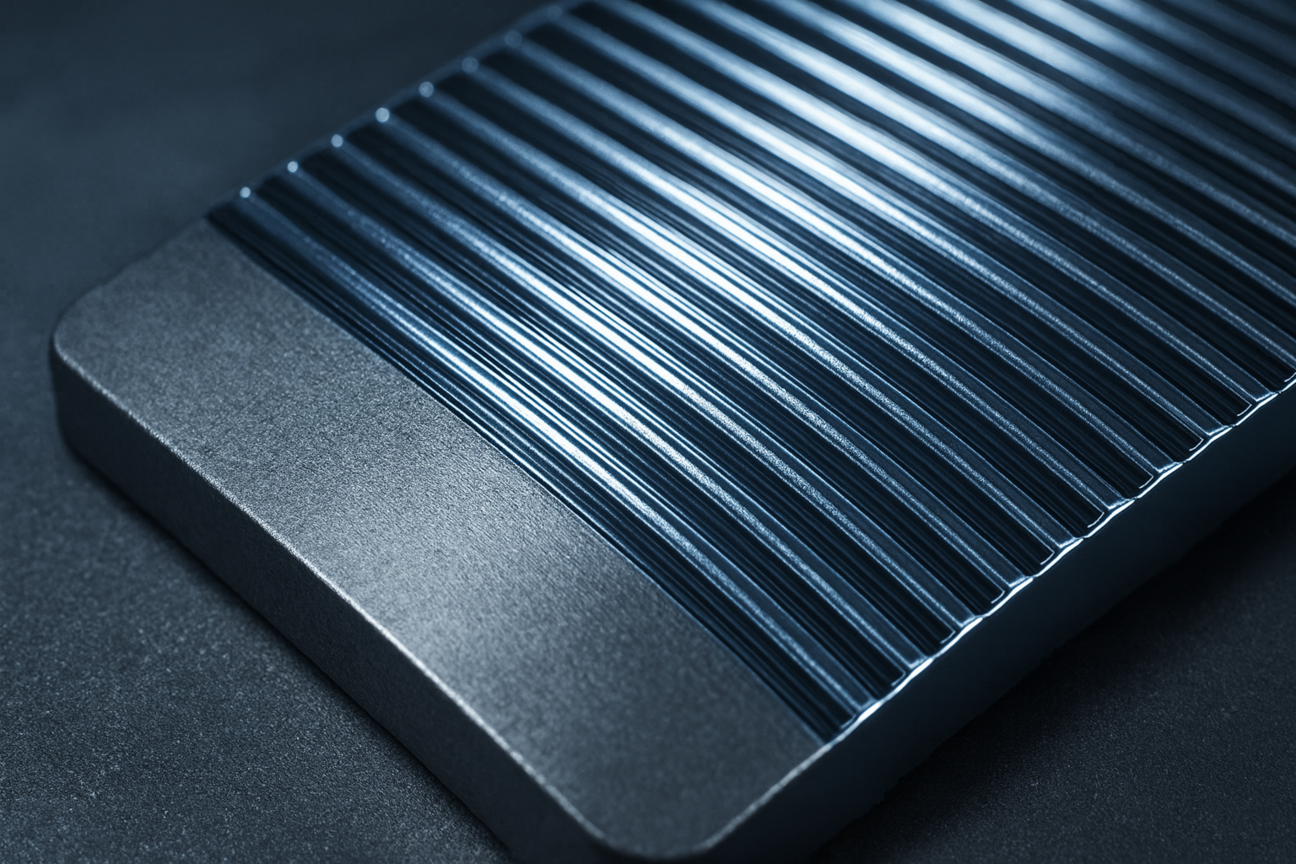

Refinement of high-performance materials: When coatings make the difference

Refinement of high-performance materials: When coatings make the difference

Molybdenum, titanium and technical ceramics are among the most exciting high-performance materials of our time.

They score points with strength, temperature stability and - in the case of titanium & ceramics - low weight and corrosion resistance.

This makes them key materials in industries such as aerospace, medical technology, electronics and energy technology.

However: even high-performance materials have limitations.

.

- Molybdenum → susceptible to corrosion at high temperatures in oxidising atmospheres

- Titanium → top for lightweight construction, but susceptible to adhesive wear & unstable coefficients of friction

- Technical ceramics (e.g. SiC). e.g. SiC) → thermally strong, but not conductive & hard to wet → makes bonding & soldering difficult

So the exciting question is: How do we get more out of these materials?

The answer lies in functional coatings - and this is exactly what the De Martin Group specialises in.

With specific pre-treatments and hybrid coating technologies we create metallised surfaces on demanding substrates. We use chemical & galvanic coatings such as nickel and chrome as well as PACVD coatings.</p

The added value:

- Better electrical conductivity & contact performance

- Higher corrosion & wear protection

- Reliable soldering & bonding

- High-quality, optically refined surfaces

Would you like to find out more? We look forward to hearing from you.