BORDEM® Cr

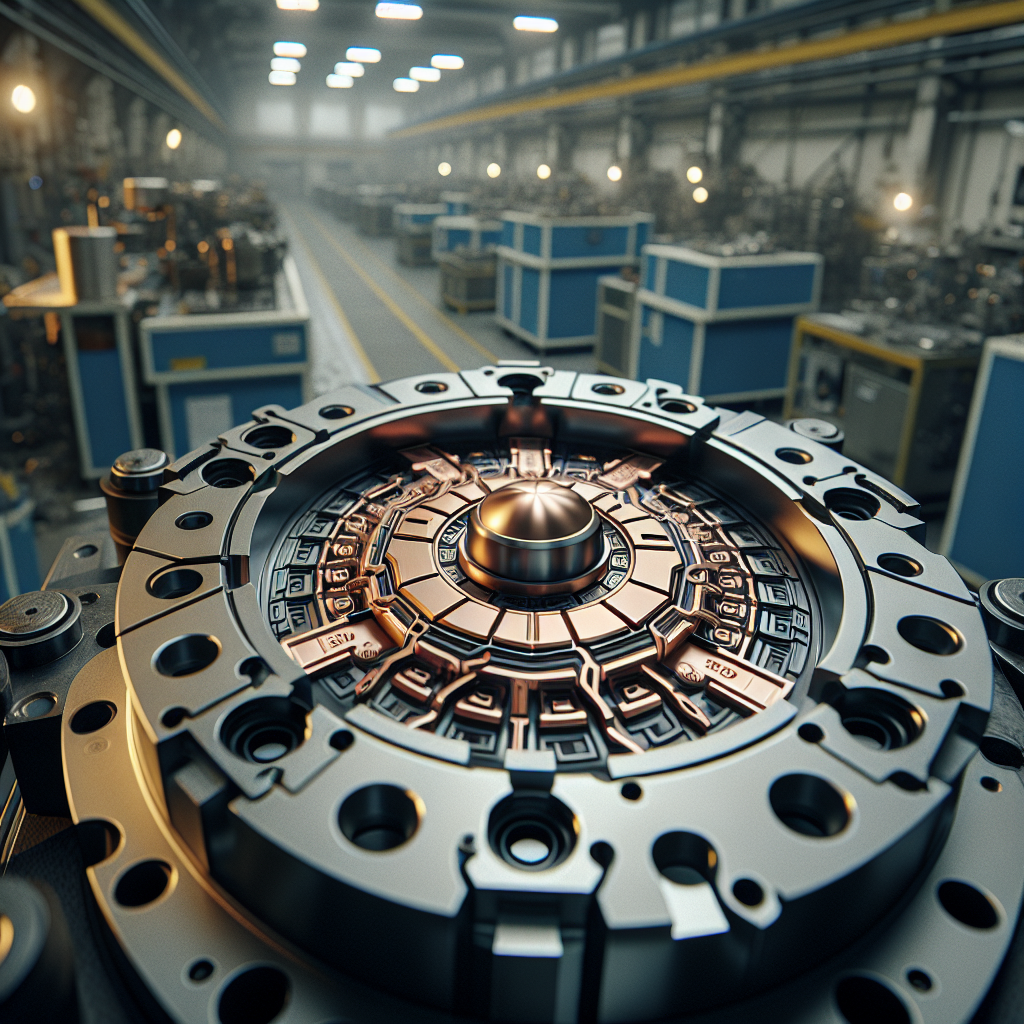

BORDEM SV: The advanced coating technology for mould cores

The BORDEM® SV coating is an innovative solution for mould tool construction, especially for the production of plastic parts with mould cores made of copper-based materials. This coating technology combines the benefits of electroless nickel dispersion coatings with the properties of chromium to enhance the surfaces of copper-based mould cores.

Properties and benefits

- Increased wear resistance: The coating minimises wear on the mould cores, resulting in a longer tool life and reduced costs.

- Improved dimensional accuracy: The coating ensures precise dimensional accuracy over longer periods of time, ensuring the quality of the parts produced and reducing scrap or reworking costs.

- Easier de-adhesion: The BORDEM® SV coating facilitates the de-adhesion of the plastic parts from the mould, which increases production efficiency and improves the surface quality of the finished parts.

- Excellent corrosion resistance: In addition to outstanding wear resistance, the coating also offers excellent corrosion resistance, making it a modern and resilient alternative to hard chrome plating.

Application area

The BORDEM® SV coating is mainly used in mould tool construction, especially in the production of plastic parts with mould cores made of copper-based materials. It is particularly suitable for applications where both high wear resistance and good corrosion resistance are required.

Summary

The BORDEM® SV coating is a specialised solution that optimises the performance and durability of mould cores in plastic injection moulding through its unique properties, thus contributing to more efficient and high-quality production. By combining electroless nickel dispersion coatings with the properties of chromium, it offers a comprehensive solution to the challenges of mould tooling.

Specifications

Applications

- Corrosion

- Friction

- Wear

Physical properties

Mechanical properties

< 700 HV0.02 as coated

- Good corrosion resistance

- Salt spray test DIN 50021 <400h

- Kesternich test DIN 50018 7 cycles (SFW 2.0)

- Low coefficient of friction

- Excellent deformation behaviour with thermoplastics

Coatable materials

- Steel, stainless steel

- Nickel and nickel alloys

- Copper and copper alloys

- Aluminium and aluminium alloys

- Titanium and titanium alloys

Processing behaviour after coating

- Polishing

- Precision turning

- Precision grinding

- Pre-treatment: Microblasting optional

Industries

- Mould making

- Medical technology

- Machinery industry

- Semiconductor industry / Semiconductors

- Textile machinery industry

- Energy and electrical engineering

- Mould and tool making

- Plant and apparatus engineering

- Armaments industry

- Automotive industry

Remarks

- Hydrogen from the coating process can lead to hydrogen embrittlement. This should be avoided by the choice of materials or post-treatment at 180°C.

- Optional heat treatment at 250 - 300°C

- Partial coating possible