DEMARTIN Chrome Boost

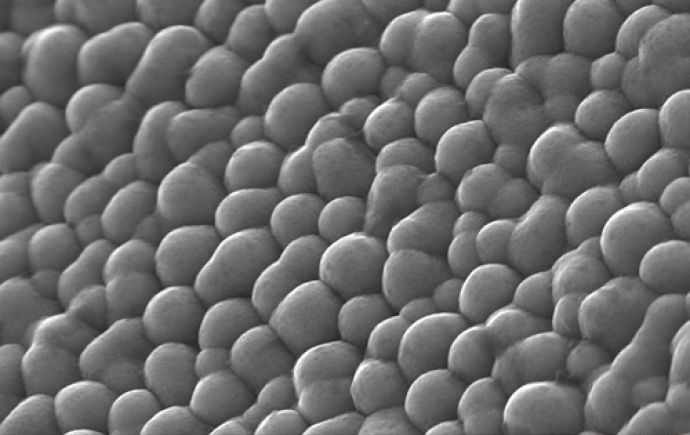

The pearl chrome, also known as thin dense chrome (TDC), which has a fine spherical structure, represents a cutting-edge innovation in surface technology. This coating solution has been specially developed for heavy-duty industrial applications and offers superior performance thanks to its unique structure and outstanding properties.

Perlchromium, known as "Cr Boost", is an advanced surface coating technology that aims to significantly improve the durability and performance of metallic materials. This coating is realised by electrolytic deposition of chromium from a chromic acid solution under specially controlled conditions. The use of modulators in the electrolyte creates a unique pearl structure on the surface that is not only aesthetically pleasing but also functionally superior.

Advantages

- Increased component life due to superior hardness and wear resistance

- Reduced maintenance costs due to improved corrosion resistance

- Higher operating efficiency due to reduced friction and improved sliding properties

- Lower mating body wear

- Cost efficiency by extending maintenance intervals and minimising downtime

- Adaptable to customer-specific requirements, which ensures broad market acceptance

- Improved product performance promotes customer satisfaction

Specifications

Combinable with galvanic and chemical undercoats, PVD coatings and inorganic topcoats

Applications

Chromium Boost is used in a variety of industries that require high wear and corrosion resistance. The coating shows superior behaviour in dynamic applications where abrasion and mechanical wear are prevalent. In addition, the bead structure improves lubricant retention, leading to a reduction in friction and wear in moving parts.

The hard chrome coating with pearl structure is used in various industries, including:

- Automotive industry: For components such as piston rods, cylinders and transmission parts

- Aerospace industry: In critical applications such as landing gear parts, hydraulic systems and turbine components

- Mechanical engineering: In highly stressed machine parts such as shafts, bearings and gears

- Oil and gas industry: For drilling and production equipment that operates under extreme conditions

Physical properties

and show no significant changes in structure or properties.

Mechanical properties

- High surface hardness

- Improved fatigue strength and fatigue resistance

- Increased load capacity and lower coefficients of friction

- Excellent tribological properties with inadequate lubrication

Coatable materials

- Steel and stainless steel

- Aluminium and aluminium alloys

- Copper and copper alloys

- Titanium and titanium alloys after hybrid pre-treatment

Industries

- Machinery industry

- Textile machinery industry

- Energy and electrical engineering

- Mould and tool making

- Plant and apparatus engineering

- Armaments industry

- Automotive industry