CERODEM® CrN

Powerful alternative to hard chrome coating. It has high oxidation resistance with good ductility.

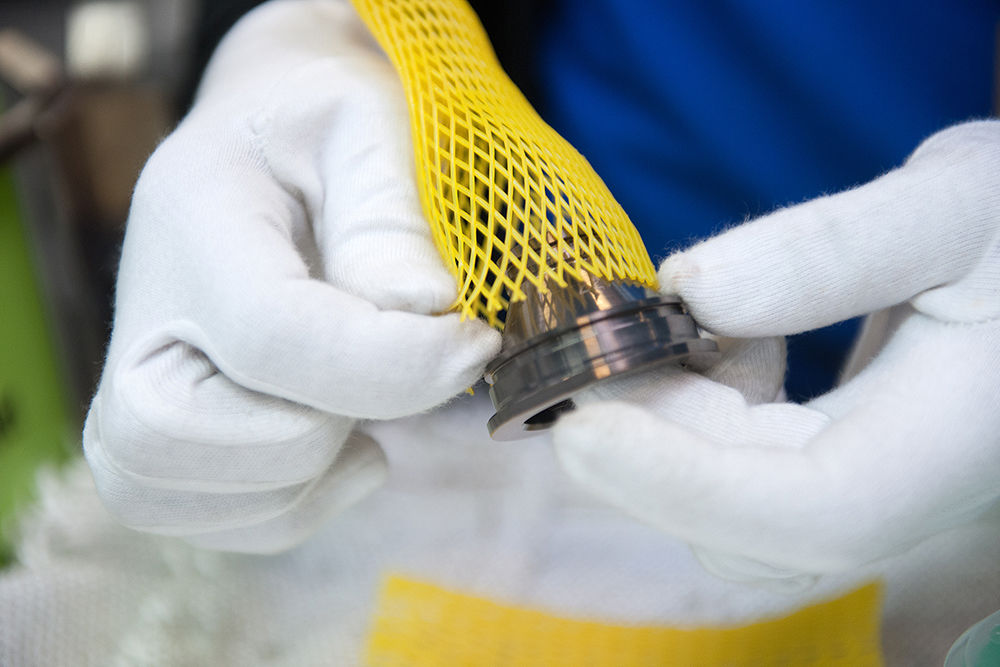

This PVD-deposited coating is used as a thin protective layer against frictional wear in non-dry applications and against abrasive wear, as well as a base layer for the carbon coating family.

CERODEM® CrN is a sputtered, smooth chromium nitride (CrN) coating. It has high oxidation resistance with good ductility. It is primarily used for components that must have good sliding properties at high temperatures. Its inherent topography, ductility and wear resistance therefore make this coating a high-performance alternative to hard chrome plating for suitable applications. Due to its behaviour towards polymers, the coating is ideal for plastic injection moulds and other polished moulds.

Specifications

typ. 2.5 +- 0.7 µm

up to 450mm L

Applications

- Tool industry

- Machine components

- Automotive suppliers

- Racing

- Textile industry

- Freighting equipment

- Aerospace

- Energy and electrical industry

- Cutting and moulding tools

- Military technology

Physical properties

Mechanical properties

Excellent abrasive wear resistance

Industries

- General mechanical engineering

- Automotive

- Plastic mould making

- Textile industry

- Food

Process variants

- Low temperature

- Multilayer with PVD and galvanic layers layer hardness variation

- Optional mechanical pre-treatment by polishing or blasting